How a CNC Machine Shop Services Your Needs Top-end CNC machine shops pride themselves on being one-stop-shops for their customers’ machining needs. This requires a lot of strong vendor relationships: the best foundries can help with casting design, while tooling vendors provide the best-in-class tools to cut a part. Once these designs are converted into […]

Benefits of a CNC Machine Shop

Benefits of a CNC Machine Shop A CNC machine shop can produce products and parts more quickly and accurately than traditional manufacturing methods. This can help businesses reduce lead times and meet customer demands more quickly. They also can save money by working with a third-party shop that will not require them to invest […]

How CNC Milling Machines Save Time and Money

How CNC Milling Machines Save Time and Money CNC milling machines are great for creating durable, precise parts that would be expensive, time-consuming or impossible to make by hand. But this subtractive manufacturing process can be costly if the part design is not optimized. Adding internal corner radii, minimizing the depth of pockets, designing tapped […]

CNC Machine Shop Medical Device Manufacturing

CNC Machine Shop Medical Device Manufacturing Medical device manufacturing is an intensely iterative process. Even if a product makes it through the initial development and design stage, it still needs to pass compliance standards before making it to the market. To do this, companies must follow strict ISO and FDA guidelines. These often include specialized […]

Advantages of Working With a CNC Machine Shop

Advantages of Working With a CNC Machine Shop A cnc machine shop needs to offer a variety of services. These include machining, painting, and impregnating. They also need to provide a high level of quality assurance. A good cnc shop will have an independent quality assurance team. This will help to reduce production time and […]

Things to Look For in a Dallas CNC Machine Shop

Things to Look For in a Dallas CNC Machine Shop A CNC machine shop is a great place to manufacture parts for a wide variety of industries. However, there are some things you should look for before settling on one. We at Bates Machine and Mfg. are here to help. For example, how stringent the […]

Benefits of Using a CNC Milling Machine

Benefits of Using a CNC Milling Machine Using a cnc milling machine allows businesses to produce bespoke parts for their products in-house, instead of paying third-party manufacturers to do it for them. This can help them save time and money. Unlike manual milling, CNC milling machines can run on their own, producing consistent results every […]

Benefits of a CNC Milling Machine

Benefits of a CNC Milling Machine A cnc milling machine uses a mechanical process to cut materials and create products. Engineers design 3D products using CAD software, then input the program into the milling machine through a computer interface. While soft materials like wood and foam can be cut on a router, stronger metals such […]

Choosing a CNC Machine Shop

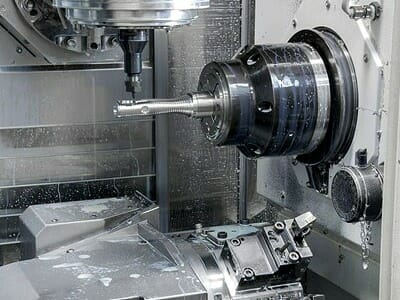

Choosing a CNC Machine Shop Machine shops rely on computer numerical control (CNC) to operate their machines. This technology replaced the hand-cranks and levers of old, and enables shop owners to create precise, customized parts with speed and ease. Businesses and product developers need a machine shop with experience handling their specific machining needs. Look […]

How to Choose a CNC Machine Shop

How to Choose a CNC Machine Shop Whether you need tons of tiny metal plates bent to a precise angle or a large panel punched to order, CNC precision machining is the way to go. The right shop can handle it all. Owens Industries in Lexington, KY specializes in machining complex components for medical manufacturers […]

What to Look for in a CNC Machine Shop in Dallas Texas

What to Look for in a CNC Machine Shop in Dallas Texas A cnc machine shop is a place where CNC machining or subtractive manufacturing takes place. This type of machining offers a cost-effective method of producing products. A CNC machine shop will usually have several machines for production purposes. These include a milling machine, […]

Why Choose a CNC Machine Shop in Dallas, Texas

Why Choose a CNC Machine Shop in Dallas, Texas? Dallas, Texas is the fastest growing metro area in the country and is home to many diverse industries. These include oil and gas, health care, telecommunications, and more. The oil and gas industry in Texas relies on high quality CNC machining to manufacture complex components like […]

The Benefits of a CNC Machine Shop

The Benefits of a CNC Machine Shop CNC machine shops use computer numerical control (CNC) machines to cut raw materials into a certain shape. They also offer post-processing services like painting, polishing and anodizing. However, even the best-designed machines need a few human skills to operate them effectively. These include problem-solving, technical knowledge, and attention […]

Top 7 Tips For Selecting a CNC Machine Shop

Top 7 Tips For Selecting a CNC Machine Shop Choosing the right cnc machine shop for your project is a crucial part of ensuring that your parts are delivered on time and to a high standard. Here are the top 7 tips to help you select the right one for your needs: It’s also important […]

Three Things to Keep in Mind When Looking for a CNC Machine Shop in Dallas

Three Things to Keep in Mind When Looking for a CNC Machine Shop in Dallas If you are looking for a quality machine shop in the Dallas area, you will want to consider some factors that will help you find the perfect match for your needs. Here are three of the most important things to […]